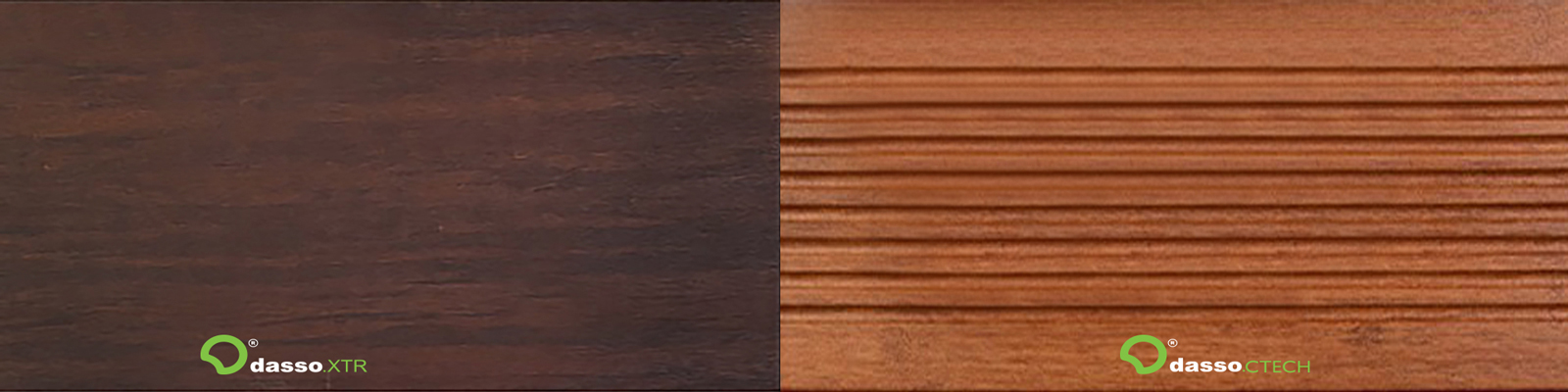

Dasso.CTECH Big Waves

Color : Royal Teak.

Global Leader and Innovators of Bamboo Products. The Next Generation Exterior Wood.

Dasso products are environment friendly, water resistant, fire retardant, termite resistant, highly stable, very low or no maintains products. Dasso is way superior in all respect as compare to any other tropical hardwoods available.